Welcome To Iceburg Technocast Private Limited

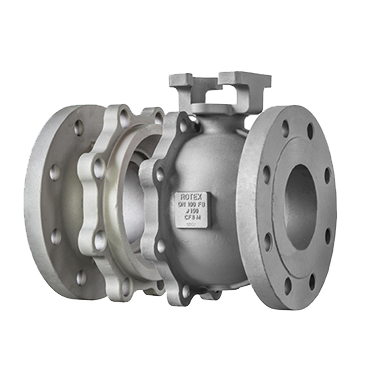

ICEBURG TECHNOCAST PRIVATE LIMITED is one of the reputed manufacturers and suppliers of Investment Castings (Lost Wax / Feinguss / Microfusion Process) in the country, situated at Rajkot, Gujarat State, INDIA. Quality of our products has been widely acknowledged to the tune of entire satisfaction of our more than 50 worldwide clients and we maintain a distinct status in our field and discipline in the country.

Our Profile

Mission

We are committed to delivering superior customer production, operational excellence, quality products, fair prices and devotion to our customers.

Quality Policy

To maximize customer satisfaction in term of Product quality as per their requirement, in time delivery Read More

Environment Policy

We at ICEBURG TECHNOCAST PRIVATE LIMITED.- INDIA are committed to protect our Environment and Earth. Read More

Health & Safety Policy

We at ICEBURG TECHNOCAST PVT. LTD. - INDIA is committed to provide safe & Healthy work environment for all employees. Read More

- We enrich with more than 24 years of experience and expertise in lost wax process technology with highly qualified and dedicated workforce and technocrats.

- We have a state of the art manufacturing facility with ultra modern and high tech machinery along with skilled operators.

- Stable & Consistence production quality.

- Shorter Sample/Prototype casting development Time.

- Manage Flexibilities in Quantity (Large scale or few Pcs to be produce).

- Individual Customer Relation Manager for execute Trunkey project order. (Single Window Monitoring)

- Quick Resonance of RFQs

- Introduced WEB ORDER MONITORING SYSTEM to trace out production cycle at buyer end.

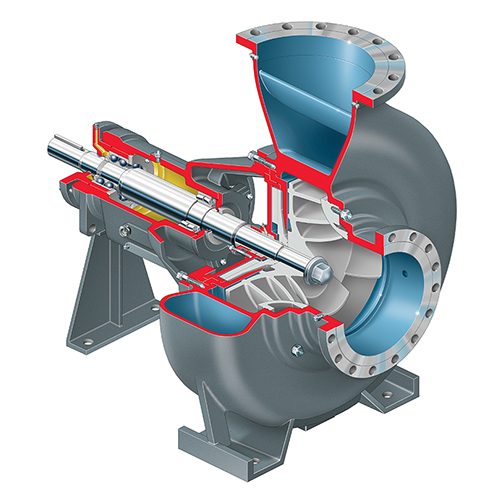

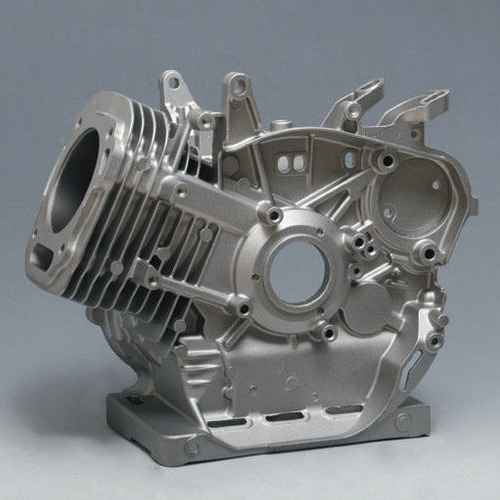

- Provide design Assistance to convert product from Sand casting, fabrication or other process parts to INVESTMENT CASTING with cost effectiveness. (Saving of Weight, less machining cost, achieve critical shapes & better Finish.)

- Can develop Casting from ready samples (Reverse Engineering).

- Annual Production Capacity: 1300 MT/Year

- Maximum Size to be Produce in Investment Casting: 500mm (L) X 450mm (W) X 450mm (H)

- Capable to produce casting Weight Range few grams to 140 Kilograms per piece.

- Catering both FERROUS & NON-FERROUS Investment Castings as per various specifications like IS, BS, ASTM, DIN, JIS, GOST and other International Standard Specifications.

- Engineering (Design) Department with CAD /CAM Facility

- Use Casting Simulation Technology for pre evolution of Methoding.

- Centralized Filled Automatics & Semi-Automatic wax pattern producing machines.

- Whether controlled Coating Department with Fluidized Bed and Rain falls Machines for ceramic coating.

- De-waxing Autoclave.

- 2 Nos. Induction Melting Furnaces (350 KW & 250KW) connected with 300 kg of 4 Nos & 100 Kg 1 No Crucibles.

- Gas fired semi automatic Heat-Treatment furnace, Calibrated as per API 6A 20th Edition Annexure-M & API 6D 24th Edition Annexure-F.

- Well equipped fettling department.

- Surface treatment process like Grit Blasting, Shot Blasting, Electro Polishing & Acid Pickling & passivation.

- High-tech & ultra modern equipped machining department

- Well equipped Quality control Department and trained staff for Visual & Dimensional inspection

-

Well equipped laboratory with facilities like,

- Material testing by SPECTROMETER having Fe, Ni, Co, Cu, Al Base with Nitrogen.

- Digital Universal Testing Machine with extensometer for 0.2% proof stress.

- Impact Testing Machine (ASTM & ISO) for cryogenic test upto -196°C

- Hardness Testing Machine.

- Microstructure analysis (Image Analysis System).

- Intergranular corrosion (IGC) Testing with different practices.

- Non Distractive testing like MP, DP, UT, RT. With ASNT Level II Qualified technical Staffs

- Regular Supply Casting with EN 10204 3.1 certificate & can provide EN 10204 3.2 certification from various TPI agencies inspection like TUV, BUREAU VERITAS, DNV, LLOYDS etc.

Group of Companies

Foundry Approvals

- ISO 9001:2008

- PED 97/23/EC

- AD 2000 Merkblatt WO

- NORSOK M-650

- INDIAN BOILER REGULATION(IBR) APPROVED

- ISO 14001 : 2004

- OHSAS 18001 : 2007